THEORETICAL ASPECTS OF MICROFILTRATION AND ULTRAFILTRATION MEMBRANE SYSTEMS

Several definitions and equations are used to characterize all types of membranes. The nomenclature below follows EPA's Membrane Filtration Guidance Manual (U.S. EPA, 2005). The first definition is fluxFlux: Flux is the flow rate of water applied per unit area of the membrane and has units of volume/unit area/time., J, which is the flow rate of filtrateFiltrate: Filtrate is the water that has passed through the membrane., i.e., the water passing through the membrane, per unit area of membrane:

Equation 1

Equation 1

Where:

J = flux, L/hr/m2 (gal/d/ft2) or Lmh (gfd)

Qp = filtrate flow rate through membrane, L/hr (gal/d)

Am = surface area of membrane, m2 (ft2)

Note that the flux unit of L/hr/m2 is usually abbreviated as Lmh and gal/d/ft2 as gfd.

As an example of calculating flux, suppose 200,000 gal/d are flowing through a membrane with an area of 4,000 ft2. The flux would be (200,000 gal/d)/(4,000 ft2) = 50 gfd (85 Lmh).

The feed waterFeed water: The feed water is the water stream applied to the membrane unit. recovery, R, is defined as the percentage of water fed to the membrane unit that actually passes through the membrane, i.e., the filtrate, and does not account for any water used in backpulseBackpulse or backwash: 1) Backwash is a procedure in which periodically the flow direction is reversed through the membrane for a short period of time in order to remove particulates accumulated at the membrane surface. 2) Backwash also refers to the waste water produced as a result of the backwash procedure. or chemical cleaningClean-in-place (CIP) or in-situ chemical cleaning: Clean-in-place is a procedure performed periodically to clean a membrane more thoroughly than backwashing can achieve in order to restore the permeability of the membrane towards baseline levels. The process uses chemicals such as citric acid and chlorine or others to remove accumulated foulants on the membrane.:

Equation 2

Equation 2

Where:

R = recovery of the membrane unit as a percentage

Qf = feed water flow to the membrane unit, L/hr (gal/d)

Of course a general flow balance would then be:

Equation 3

Equation 3

Where:

Qc = concentrateConcentrate: Concentrate refers to the waste stream created in reverse osmosis and nanofiltration systems or any membrane system in which not all the feed water passes through the membrane. The water that does not pass through the membrane will have a much higher concentration of dissolved solids and/or particulates. or reject flow from the membrane unit, i.e., feed water which does not pass through the membrane and leaves the unit untreated, L/hr (gal/d)

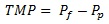

The pressure difference across the membrane is what drives the water flow through the membrane. It is called the transmembrane pressure, TMPTransmembrane pressure (TMP): The transmembrane pressure is the difference in pressure between the feed water side and filtrate side of a membrane., and is:

Equation 4

Equation 4

Where:

TMP = transmembrane pressure, psi

Pf = pressure on the feedwater side of the membrane, psi

Pp = pressure on the filtrate side of the membrane, psi

Note that the pressures need not be constant along the membrane in which case averages may be appropriate depending on the purpose.

Since the TMP is the driver of the membrane flux, an equation can relate the two:

Equation 5

Equation 5

Where:

Jt = flux at temperature T, Lmh (gfd)

Rt = total membrane resistanceResistance: Resistance or membrane resistance is a measure of the difficulty of passing water through a membrane due to the nature of the membrane itself or to foulants accumulated on the membrane surface., psi/gfd-cp

µT = viscosityViscosity: Viscosity is a measure of the internal resistance of fluids to flow, e.g., honey has a much higher viscosity than water. The viscosity of water will control how much pressure or head loss is needed to force it through a membrane. The viscosity of water will increase with decreasing temperature and thus winter operation will see higher transmembrane pressures to maintain the same flux. in centipoises at water temperature T, cp

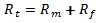

The total membrane resistance, Rt, is composed of the intrinsic membrane resistance and the resistance of the foulant layer on the membrane:

Equation 6

Equation 6

Where:

Rm = intrinsic membrane resistance, psi/gfd-cp

Rf = resistance of the foulant layer, psi/gfd-cp

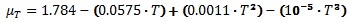

Note that as the water temperature goes down, the viscosity goes up and therefore by equation 5, the flux rate would go down unless the TMP is increased. The EPA Guidance Manual provides an equation to estimate the viscosity as a function of temperature:

Equation 7

Equation 7

Where:

T = water temperature, oC

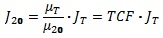

Because water temperature can have a significant effect on viscosity and thus membrane flux, the flux at any temperature is often normalized to what the flux would be at 20oC via the following equation:

Equation 8

Equation 8

Where:

TCF = temperature correction factor for flux = µT/µ20

Since the flux is linearly dependent on the TMP as shown in equation 5, it is also often desirable to normalize the flux for different TMPs by simply dividing the flux by the TMP to give the temperature and pressure normalized flux which is called the specific flux and is essentially the expected flux through the membrane at 20oC and a TMP of 1 psi:

Equation 9

Equation 9

Where:

M20 = temperature and pressure normalized flux or specific flux, gfd,psi

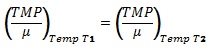

By combining several of the equations above, the following relationship between TMP and viscosity can be derived which can be used to predict TMP's and viscosities in order to maintain a constant flux:

Equation 10

Equation 10

For example, let us say that a membrane system is operating at a TMP of 9 psi at 25oC. If the temperature drops to 10oC, what must the TMP be to keep the same flux? Since the viscosities at 25oC and 10oC are 0.890 cp and 1.307 cp respectively. Thus, the TMP at 10oC must be (9 psi)(1.307/0.890) = 13.2 psi, i.e., 47% higher.

One further definition that may be useful is the volumetric concentration factor, VCF, which is the ratio of the concentration of suspended solids on the feed side of the membrane to that of the influent feed concentration:

Equation 11

Equation 11

This ratio is useful in concerns about integrity breachesIntegrity breach: A breach refers to leakage in the membrane module due to a broken fiber, leaking seal or other leak that can allow microbes and particulates to bypass the membrane and pass directly into the finished water. and the consequent potential for contamination of the filtrate.