PROCESS DESCRIPTION

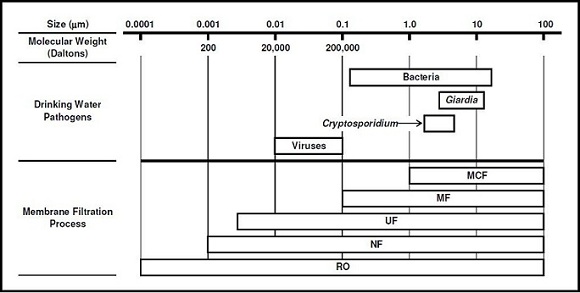

Membrane processes are classified microfiltration (MF)Microfiltration (MF) membranes: Microfiltration membranes are typically hollow-fibers with a pore size range of approximately 0.1 – 0.2 μm (nominally 0.1 μm)., ultrafiltration (UF)Ultrafiltration (UF) membranes: Ultrafiltration membranes are typically hollow-fibers with a pore size range of approximately 0.01 – 0.05 μm (nominally 0.01 μm)., nanofiltration (NF)Nanofiltration (NF): Nanofiltration is a pressure driven membrane process that uses reverse osmosis to remove dissolved materials. Nanofiltration applications are typically for softening or organics removal. or reverse osmosis (RO)Reverse osmosis (RO): Reverse osmosis is the reverse of the natural osmosis process, i.e., the passage of a water through a semi-permeable membrane from a solution of higher concentration of dissolved solids to a solution of lower concentration. Reverse osmosis applies a high pressure on the higher concentration side of the membrane to drive water through the membrane against the concentration gradient, in order to produce a water with a lower concentration of dissolved solids. depending on their removal mechanism and target contaminants. Membrane cartridge filtrationCartridge filtration: Cartridge filtration uses disposable filter elements. The pore sizes can be the same as typical microfiltration membranes and the units could meet the definition of a membrane filter under the LT2ESWTR but often the pore sizes are much larger. (MCF) could be considered as another category. Figure PD.1 below shows the general classes of membrane filtration and the sizes of material relevant to each. "Membrane filtration" typically refers to just MF and UF membrane systems and these are the subject of this educational module.

Figure PD.1. Filtration Application Guide for PathogenPathogens: Pathogens are disease causing microorganisms. Two of the most important pathogens driving interest in membrane systems are Giardia and Cryptosporidium. Removal (USEPA, 2005)