DETERMINING UCL

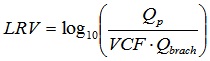

Control limit. The basic equation for determining the log removal value (LRV)Log removal value (LRV) or log reduction credit: The log removal value or log removal credit is the filtration removal efficiency for a target organism, particulate, or surrogate expressed as log10(feed concentration) – log10(filtrate concentration). from a pressured based integrity test is based on a mass balance of particles escaping through a breachBreach or integrity breach: A breach refers to leakage in the membrane module to due a broken fiber, leaking seal or other leak that can allow microbes and particulates to bypass the membrane and pass directly into the finished water. into the filtrateFiltrate: Filtrate is the water that has passed through the membrane.:

Equation 1

Equation 1

Where:

Qp = membrane unit flow rate

VCF = volumetric concentration ratio which is the ratio of the concentration of contaminants passing through the breach to the concentration in the feed waterFeed water: The feed water is the water stream applied to the membrane unit. which would be one for a membrane operated as a dead end system as compared to a cross-flowCross-flow configuration: A cross-flow configuration is the application of water at high velocity tangential to the surface of a membrane to maintain contaminants in suspension. system

In chapter 4 of the EPA Membrane Filtration Guidance Manual the theory is developed in detail to convert this basic equation into one that can be applied to pressure-based integrity tests that monitor either the air flow or pressure decay.

Similarly, the basic equation for determining the log removal value (LRV) for a marker-based direct integrity test is:

LRV = Log10(Cf) - Log10(Cp)

Equation 2

Where:

LRV = direct integrity test value of LRV

Cf = the typical feed concentration of the marker used in the test

Cp = the filtrate concentration of the marker from an integral membrane unit.

Note that section (iii) of the direct integrity testing requirements of the LT2ESWTRLT2ESWTR: The Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) is an EPA regulation targeting control of Cryptosporidium and other microbial contaminants. It mandates treatment efficiency, i.e., log removal values, and gives credit to various treatment technologies to achieve the needed treatment efficiency. states: "The direct integrity test must have a sensitivity sufficient to verify the log treatment credit awarded to the membrane filtration process by the State, where sensitivity is defined as the maximum log removal value that can be reliably verified by a direct integrity test." In other words if the sensitivity of direct integrity testing is less than the LRV assigned by the state, then the sensitivity would control. E.g., if the state awarded 4 log removal credits but direct integrity testing is only capable of showing 3 log removals perhaps because of poor monitoring techniques and regardless of how good the actual removal is, then the state would not allow more than 3 log removal credits. Again, the EPA Membrane Filtration Guidance Manual discusses in detail the development of equations for the sensitivity of direct integrity tests.

As stated previously, the LT2ESWTR requires daily integrity testing even if a unit is on-line for only a fraction of a day. The state may require more frequent testing or less frequent testing than daily although less frequent testing would require supporting documentation such as a history of demonstrated reliability in similar situations. The membrane unit is taken off-line for pressure-based direct integrity testing and is usually taken off-line for marker-based tests as well.

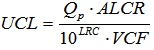

In order to insure that a membrane unit is achieving the needed log removal value (LRV) for Cryptosporidium, an upper control limitControl limit (CL): A control limit in membrane systems refers to a response from an integrity test, for example exceeding a maximum allowable rate of pressure loss, that triggers a response by the operators such as searching for breaches. (UCL) must be established. And as stated previously, if the UCL is exceeded then the membrane unit must be taken off-line for further testing, repair, and maintenance. Other lower control limits can be established as indicators of the severity of any problem but it is the UCL that must trigger a response. For pressured-based direct integrity tests the UCL will be a flow of air or a pressure decay rate which if exceeded triggers the unit to be taken off line. For a marker-based test, the UCL would simply be the log removal credit awarded by the state. The equations for establishing the UCL for a pressure-based direct integrity test are:

For an UCL in terms of air flow rate:

Equation 3

Equation 3

Where:

UCL = upper control limit in terms of airflow, L/min

Qp = membrane unit design capacity, L/min

ACLR = air liquid conversion ratio, dimensionless

LRC = log removal credit awarded, dimensionless

VCF = volumetric concentration factor, dimensionless

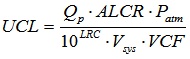

For an UCL in terms of pressure decay rate:

Equation 4

Equation 4

Where:

UCL = upper control limit in terms of pressure decay rate, psi/min

Qp = membrane unit design capacity, L/min

ACLR = air liquid conversion ratio, dimensionless

Patm = atmospheric pressure, psia

LRC = log removal credit awarded, dimensionless

Vsys = volume of pressurized air in the system during the test, L

VCF = volumetric concentration factor, dimensionless

An extensive example calculation of the UCL and other factors is presented in the EPA Membrane Filtration Guidance Manual and can be seen by clicking this link: example calculation. The calculations are complex; the membrane module manufacturer should be able to assist as needed.