|

So far, we have discussed the different aspects of a successful recirculation system separately. Success of a system, however, depends on all the components working in concert. To begin this chapter on system management let's take a virtual field trip to the Tennessee Aquarium in Chattanooga. We will get a behind the scenes tour of how that complex recirculation system works.

Fingerlings for grow out can be produced on site or purchased. Breeding your fish can save money and gives you an added measure of control over disease, but it also adds a considerable layer of complexity to any production operation. In fact, one potentially profitable approach to fish farming is to become strictly a fingerling producer. For some species, such as tilapia and trout, brood stock can be raised in the facility. For others, like hybrid striped bass, they must be obtained from the wild. Brood stock must be sexed and allowed to "ripen" (become ready to spawn). For temperate species, this usually requires mimicking the photoperiod cues typical of that approaching spawning time in nature. Some species, like tilapia, will spawn in tanks, others, such as trout, must be manually stripped of their eggs and sperm and bred artificially.

|

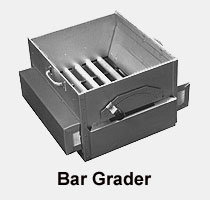

Economics demand that production units be kept at near maximum capacity. It is costly to run pumps and aerators and incur equipment depreciation for less than the maximum stocking rate of a recirculation system. This means production schedules must be carefully planned. For example, in an aeration-based tilapia system, fingerlings would be stocked at about 0.25 lb/gal (30 g/L). As they grow they must be transferred to other tanks, so as not to exceed 0.5 lb/gal (60 g/L). That means ongoing harvest must occur to free space for the new crop. This phased production also insures a continual supply for market. Individual fish do not all grow at the same rate, so when the fish are moved they are also graded. This means sorting for size, keeping like size fish together. Grading can be done manually, but more often a bar-type grader is employed. Bar width is adjusted so smaller fish slip through while larger ones are retained. With some species that are not particularly cannibalistic, like tilapia, all sizes can be reared together in the same tank. This is not particularly efficient, however, as different sizes have different optimum feeding rates and larger fish will take more than their fair share of the feed. The result is overfeeding and poor feed conversion.

As mentioned in the water quality video, water quality measurements are, at least, a daily affair. These measurements may dictate adjustments in aeration, carbon dioxide stripping, or the addition of sodium bicarbonate. As the video in the last chapter showed, fish must be periodically sampled and weighed in order to adjust the feeding rate. Most recirculation systems are constructed of plastic and fiberglass which require little routine maintenance. Even the moving parts, like blowers and pumps, usually come with sealed bearings and can run continuously for extended periods. Every hard surface in a system, however, is prone to the buildup of bacteria that feed on dissolved organic matter and ammonia. If overfeeding occurs or solids are not adequately removed, fungus may grow as well. Systems that are exposed to strong light will have algal growth. These growths will seriously slow the flow rate in pipes, so it is a common practice to clean and disinfect a unit at the end of each production cycle, even if there is no evidence of disease.

Highly loaded recirculation units are fragile systems and even modest perturbations can result in losing thousands of pounds of valuable fish. Because of this, large investments should be protected with alarms and, perhaps, emergency controls. Oxygen/temperature meters designed for continuous monitoring have an output for an alarm setting. When dissolved oxygen falls below, say, 3 mg/L, the monitor can trigger a warning bell or an automated phone dialer. Additionally, the alarm setting can automatically open a solenoid valve that allows pure oxygen or fresh water to flow into the stricken tank keeping fish alive until an operator arrives. Another benefit of continuous water quality measurement is that an electronic log can be kept. This will help in keeping fish load near, but not over, the maximum for the system.

Another automatic safeguard is a generator power back up. However, while loss of power is a common source of system failure, it is not the only one and installing automatic generator back up doesn't obviate the need for continuous monitoring and alarm.

Systematic, detailed written or electronic records are essential for production aquaculture. If a measurement is made or any action taken, even routine feeding, it should be recorded with time, date, and any comments. The resulting log can be invaluable in troubleshooting problems, calculating things like feed conversion, and identifying ways of improving the economy of the operation.

Fish, even when fresh, may have an "off flavor". This refers to the accumulation of harmless chemicals in the flesh that some consumers can smell and taste at very low concentrations. This off flavor is usually identified as a "pondy" or "muddy" taste. The chemicals occur in blue green algae and bacteria which are carried up the food chain to the fish. In recirculation aquaculture, off flavor may originate in the system or in the feed. In any case, it can be eliminated by purging. Before fish are harvested for consumption, a sample should be microwaved and tasted by an individual who is sensitive to off flavor. If it is detectable, the fish are placed in a clear water flow-through system and are not fed. They are then periodically sampled for off flavor, which should be eliminated in 4 - 8 days.

The simplest way to market culture fish is live. That way the processing is left to the consumer. Certain human cultures have a tradition of obtaining fish alive, so they are guaranteed of freshness. In large cities, ethnic food stores have tanks of live fish for sale for food. Recirculation aquaculturists have identified this as a good market niche for them to serve. Tilapia are a favorite fish for this market because they withstand transport and holding very well.

Processing plants for cultured fish only exist in a few parts of the country. Most recirculation aquaculturists must process their fish themselves if they intend to market gutted carcasses or fillets. If processing is to be done on site, a separate processing room needs to be set up. The fish farmer should familiarize himself with local health regulations and HACCP (Hazard Analysis Critical Control Points). The first part, Hazard Analysis, represents the evaluation of potential risks resulting in food poisoning. The second part, Critical Control Points, represents which specific areas have to be constantly controlled and monitored to insure food safety.