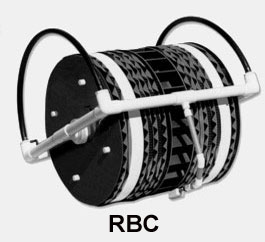

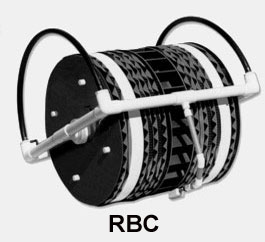

Photo Courtesy of Aquatic Ecosystems, Inc.

|

RBC's are constructed of circular, waffle-like plates attached to an axle. They are submersed about halfway into the water and slowly rotated (about 1 rpm). The plates become colonized by nitrification bacteria. While in the water the bacteria pick up ammonia and when the filter rotates up into the air oxygen diffuses into the colony. RBC's are often placed in the fish tank, but they can be installed anywhere in the system where there is room. RBC's must be powered, obviously, so that they turn. This may be accomplished by electrical motors or air lift (as in the picture to the left). Either way, energy is expended to move the filter. This is a disadvantage as energy costs are a major expense in recirculation aquaculture. Also, the fact that it is a moving part opens the door for potential break down. Wet bacterial slime is quite heavy and a fully colonized RBC weighs much more than a dry one, so they must be engineered very robustly. For example, a large biofilter must have a solid steel shaft. Some RBC's (like the one on the left) are designed to float, minimizing some of the structural concerns. On the plus side, RBC's may decrease nitrification, but they do not overflow or stop flow through the system like a clogged trickle filter. While RBC's are tried and proven nitrification technology, they are being used less in recirculation systems because of the drawbacks mentioned above.

Trickle filters have a simple design in which media is placed in a container that has a partially open bottom so water drains out. Recirculated water is then sprayed over the top and it trickles down over the media. The flow of water keeps the media wet and supplied with ammonia, while the open nature of the media allows air to circulate through the filter to supply oxygen. A trickle filter is obviously an open system so all head is lost as the water is sprayed out of the supply pipe. Because of this, the trickle filter is often placed at the highest point in the system so water can flow by gravity down through the fish tank arriving at the pump which is at the lowest place. Their simplicity, lack of moving parts, minimal energy requirements, and use of atmospheric oxygen make trickle filters the most popular nitrification equipment in recirculation aquaculture. However, they share a major drawback with RBC's (and all bacterial thin layer technology, except suspended beds). In order not to clog they cannot have specific surface areas over about 300, but in order to support enough bacteria with this surface area, the filters must have a large volume. Also, it is a major heat exchanger if you are trying to keep your water at a different temperature than your air.